If the main cable of a suspension bridge is damaged, is it truly irreparable and unreplaceable, requiring a complete rebuild?

The other day, Lawtee briefly answered a question on Zhihu about suspension bridges. While it received many upvotes, there were also numerous skeptics in the comments, mainly debating whether the main cable of a suspension bridge can be repaired or replaced. Since Lawtee knows nothing about bridge construction, I relied on basic reading skills and consulted serious literature to clarify this issue.

Comments on a Certain Bridge Fire Incident

The debate started with a question on Zhihu: "What's your take on a certain bridge closing its rightmost lane during the Qingming holiday?" Lawtee had written a simple response:

Bridge construction has learned another lesson. Who would have thought a suspension bridge could face fire risks? Probably, the main cable height will need to be adjusted to at least 10 meters in the future; otherwise, it's a real headache. At the current height, if a 3-meter-tall truck catches fire next to the main cable, the entire cable might need replacement, and the time required is anyone's guess.

Though it was a somewhat flippant answer, it garnered over 300 likes. However, the comments section became heated. Some argued, "If the main cable is burned, its strength decreases, and there could be hidden damage." Others outright stated, "The repair cost is almost equivalent to being irreparable." Some even brainstormed ideas like "laying water pipes with sprinklers" or "adding aerogel insulation," while a few speculated conspiratorially that "the vehicle was intentionally parked there to burn."

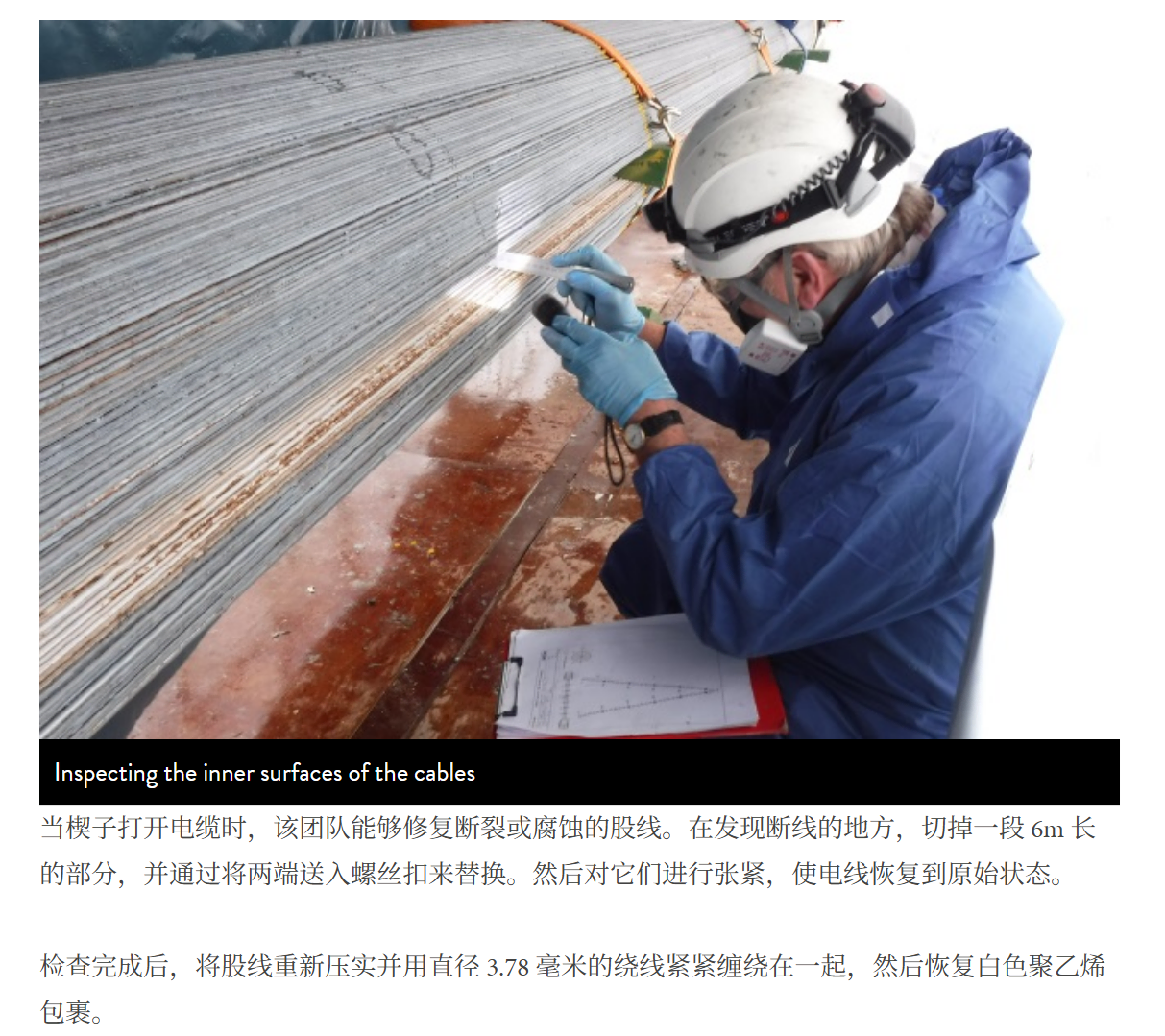

What surprised Lawtee the most was that several commenters claimed, "The main cable can't be replaced; it's sealed in the anchor block, so the beams must be dismantled first," or "Replacing one would cost hundreds of millions; if it can't be replaced, the whole bridge must be rebuilt." Initially, Lawtee admitted ignorance but later cited examples of suspender replacements, such as the Jiangyin Bridge replacing over 50 suspenders and the Runyang Bridge replacing two cables in two months. Yet, others questioned, "Those are suspenders, not the main cable." Admittedly, Lawtee hadn't realized this distinction, so I looked up the case of the UK's Severn Bridge replacing a 6-meter section of a main cable strand and added that, which finally quelled the debate.

In essence, this is a classic case of "amateurs watching for the excitement" online? When it comes to specialized topics like bridges, most people, including Old T, don't understand but still want to voice their opinions, often leading the discussion astray. So, this time, Lawtee decided to dig deeper into serious sources to see what's really going on with suspension bridge main cables.

Basic Structure of a Suspension Bridge Main Cable

First, let's talk about what a suspension bridge main cable looks like. According to the Ministry of Transport's bridge design standards and some engineering reports, the main cable is the "backbone" of a suspension bridge. It consists of thousands of high-strength galvanized steel wires bundled in parallel, each wire 5–7 mm in diameter. A single main cable typically has 127 to 271 strands (each strand is a bundle of wires), with a total diameter reaching about 1 meter. The outer layer is wrapped with protective wires and coated with anti-corrosion layers, designed to last over 100 years. Generally, a suspension bridge has one main cable on each side, anchored at both ends in massive anchor blocks, with suspenders hanging from them to support the bridge deck.

Can the Main Cable Be Repaired or Replaced?

Lawtee reviewed over a dozen papers on CNKI and found three main perspectives on this issue: irreparable and unreplaceable, extremely difficult to repair or replace, and repairable and replaceable.

- Main Cable Cannot Be Repaired or Replaced

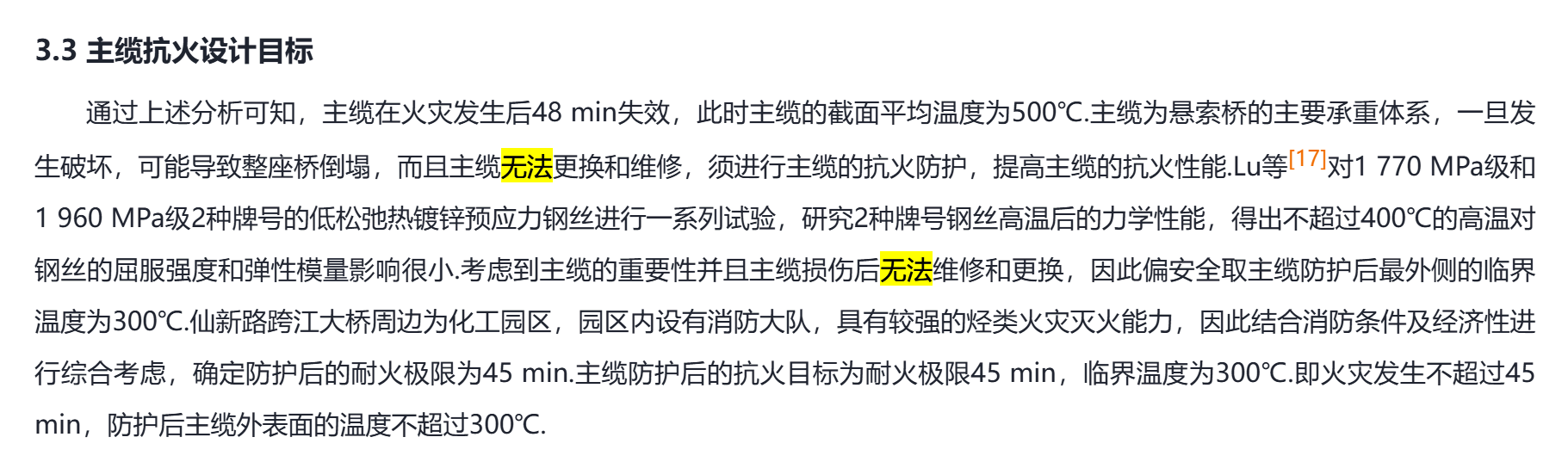

For example, in the article "Fire Resistance and Protection of Main Cables in Long-Span Suspension Bridges," the authors repeatedly state that the main cable of a suspension bridge cannot be repaired or replaced. The conclusion also emphasizes the strictest fire protection goals for main cables—45 minutes of fire resistance and a critical temperature of 300°C—based on this irreplaceability.

- Extreme Difficulty in Repairing or Replacing the Main Cable

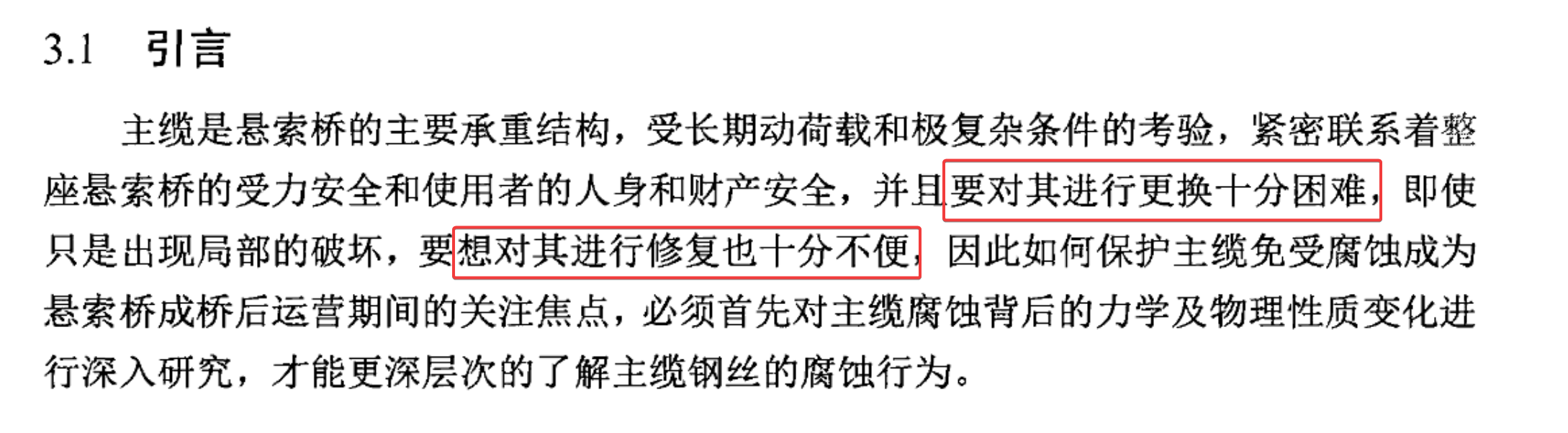

Most papers Lawtee consulted indicate that, as the core component of a suspension bridge, the main cable is designed to last the bridge's entire lifespan from the outset, making replacement or repair extremely challenging and costly.

- Main Cable Can Be Repaired or Replaced

In some more recent papers Lawtee found, there are clearly differing opinions from the earlier views. Specifically, in recent years, with the introduction of new main cable anchoring technologies, some new suspension bridges have enabled efficient replacement of main cable strands.

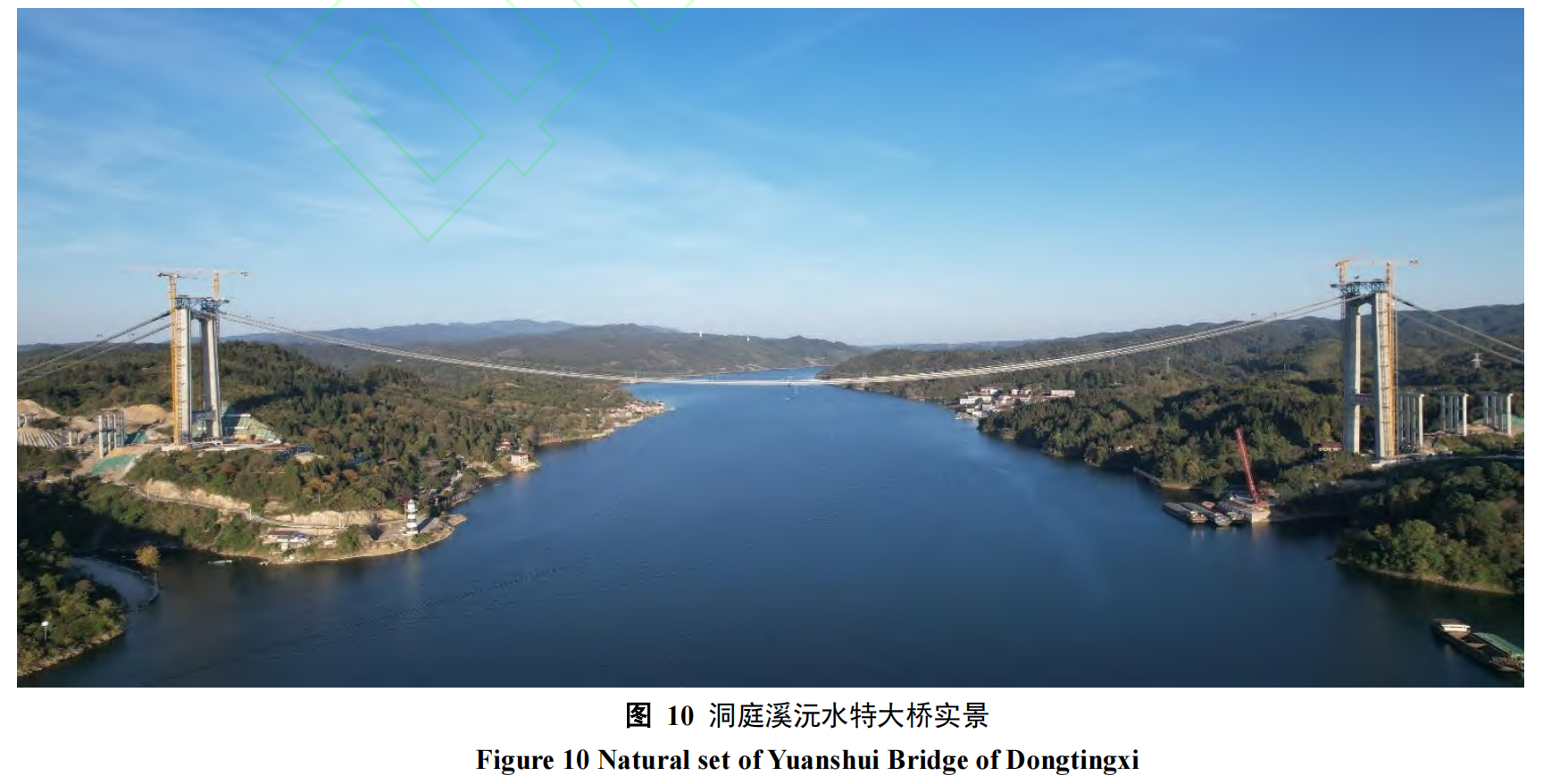

For instance, in an article titled "Design of Cable and Anchorage System for Dongtingxi Yuanshui Super-Large Bridge" from Chinese and Foreign Highway on October 23, 2025 (coincidentally today), the authors mention that the Dongtingxi Yuanshui Super-Large Bridge under construction in Huaihua, Hunan, uses a multi-strand finished cable anchoring system with good corrosion resistance and high replacement efficiency, allowing for efficient replacement of main cable strands.

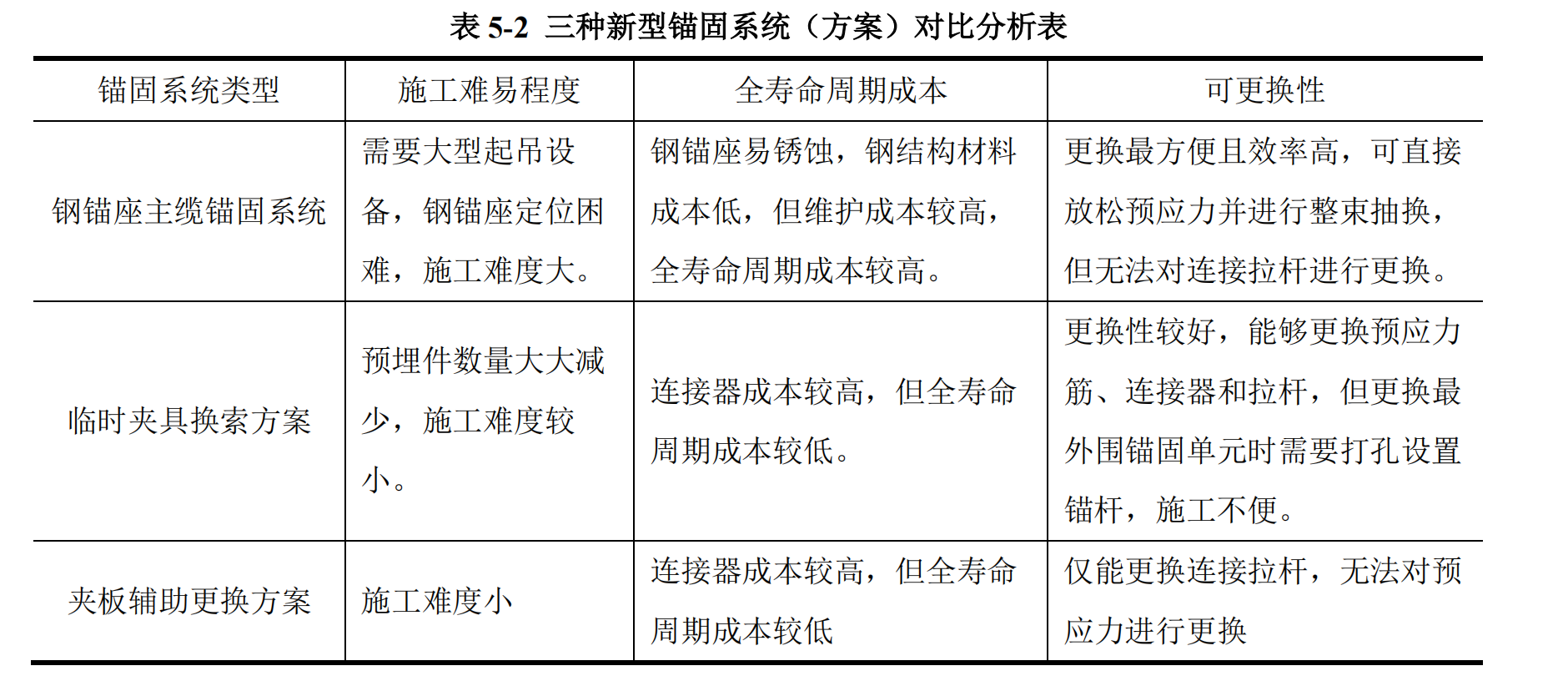

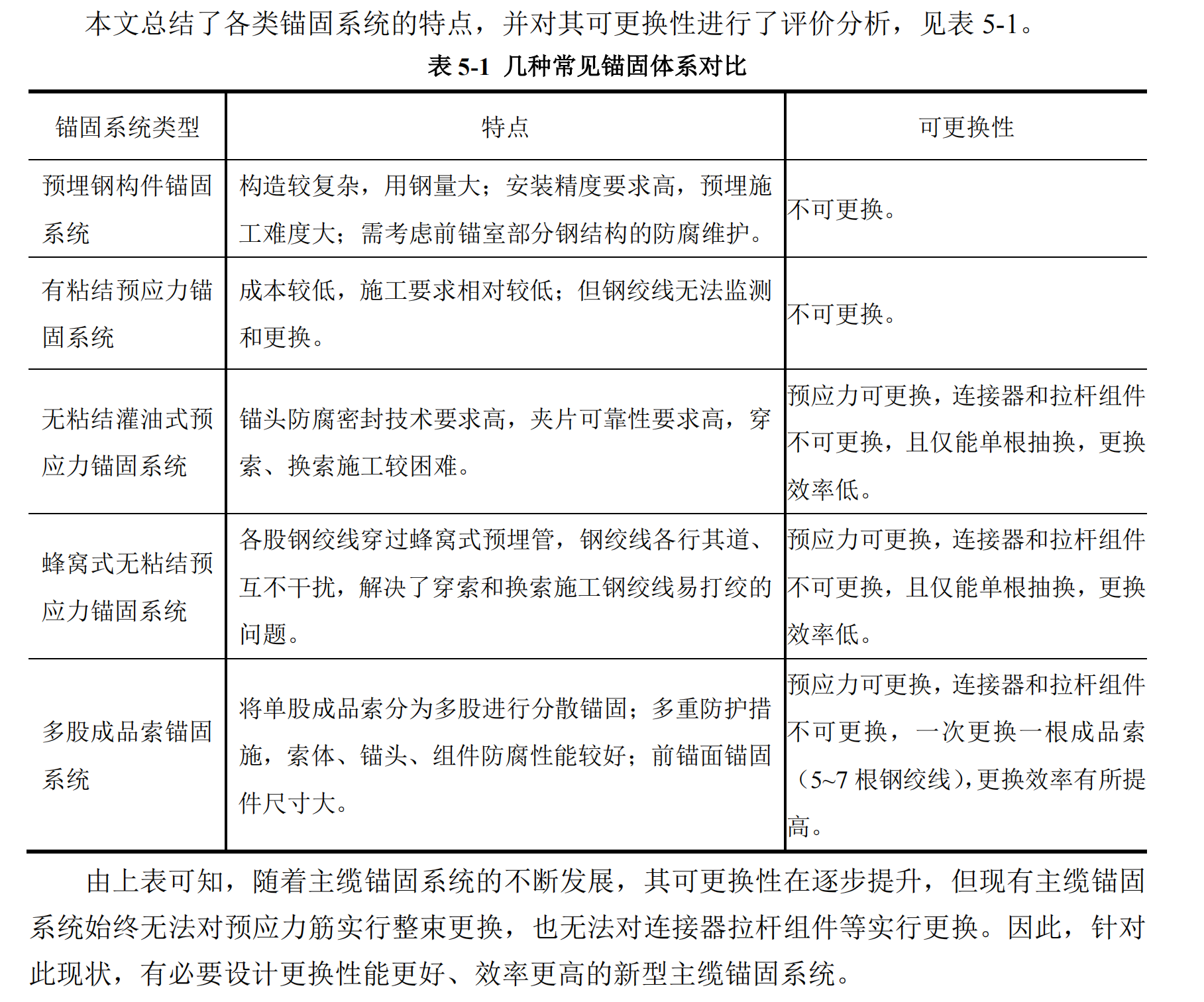

Lawtee further discovered that as early as 2022, a Southeast University paper titled "Research on Gravity Anchor Structure and Replaceable Main Cable Anchorage System for Super-Long-Span Suspension Bridges" systematically analyzed the characteristics of traditional main cable anchorage systems and proposed three new designs aimed at enabling efficient replacement of main cable strands.

Moreover, before presenting these new solutions, the author summarized past suspension bridge main cable anchorage technologies, pointing out that among the five common types of anchorage systems, only "embedded steel component anchorage systems" and "bonded prestressed anchorage systems" are non-replaceable, while "unbonded oil-filled prestressed anchorage systems," "honeycomb unbonded prestressed anchorage systems," and "multi-strand finished cable anchorage systems" are replaceable. The cost and efficiency of replacement vary depending on the technology used.

At this point, the matter is largely settled. Based on the literature Lawtee has reviewed, it's quite clear whether a suspension bridge's main cable can be repaired or replaced. For newer bridges, innovative anchorage designs likely facilitate replacement. For older bridges, limitations of the time may make replacement extremely difficult or even impossible.

However, this doesn't mean that main cables of older suspension bridges are beyond repair.

At the very least, the case of the UK's Severn Bridge, which Lawtee mentioned in the Zhihu comments, is quite illustrative. In 2016, the British repaired this modern suspension bridge, which was already 50 years old, by driving a wedge to create a workspace, cutting out a 6-meter damaged section of one strand, and reconnecting it with a screw coupler. The entire repair process only occupied 1.5 lanes in one direction and did not disrupt traffic.

Conclusion

In the end, Lawtee believes that we laypeople should maintain respect for specialized fields like bridge engineering, but we shouldn't easily give up our "thirst for knowledge." By consulting literature and seeking out case studies, we can always find clarity. Not knowing isn't shameful; being willing to research and compare is what truly counts.