Violent Repair of a Touch-Sensitive Desk Lamp

In 2012, I spent one-tenth of my monthly income on a Philips desk lamp, which served me well until around 2020 when my wife replaced it with a so-called "smart" children's lamp that cost 500 yuan. This "smart" lamp frequently suffered from touch malfunctions—no matter how I tried to touch the switch, it only responded once or twice out of ten attempts. Often, I couldn't turn it off and had to unplug it. Recently, the lamp's touch function completely failed.

Repair Process

Although it's a product that feels like a scam, I knew its only issue was the touch malfunction. I decided to take it apart to see what was going on.

Upon disassembling, I found that this lamp was indeed a disposable product. The base had to be forcibly broken to reveal six screw holes. Fortunately, even after such rough handling, the appearance wasn't affected since the damage was on the base, which isn't usually visible.

Analysis of the Repair Principle

It took a while to finally remove the touch-sensitive part of the lamp. I noticed that the touch switch mechanism was quite different from what I had imagined.

After some research, I realized that this touch mechanism uses capacitive sensing technology. The part you touch is just one side of a molded plastic piece, while the other side has a metal circuit that receives pulse signals when touched.

I watched several repair videos on Douyin (TikTok) about fixing touch-sensitive lamps, but most solutions didn't match my situation. The remaining videos suggested bypassing the touch switch entirely, either by hardwiring the circuit to use plugging as the switch or by adding an external physical switch.

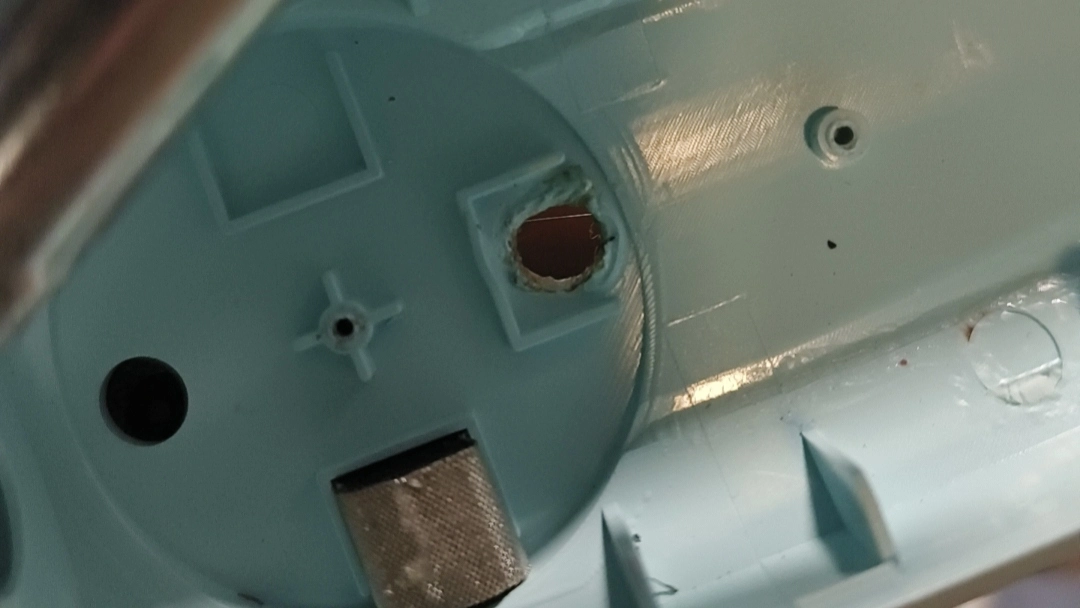

I initially thought I might have to do the same, but I wasn't ready to give up. Every time I touched the small copper-like circuits shown in the image above, the lamp would turn on or off.

I realized that the key to the repair was figuring out how to activate the small copper circuits through the molded plastic button on the right side of the image.

A simple idea was to forcibly separate the plastic part with a carving knife, turning the fixed touch into a switch-like touch.

However, during this process, I accidentally pulled off the power line from the circuit board.

So, I had to get out the soldering iron to reconnect the wires.

Using the soldering iron gave me two inspirations for the next steps in the repair.

Drilling a Hole to Activate the Internal Circuit from Outside

With the soldering iron handy, I melted a hole through the plastic of the original touch switch. This allowed me to poke something from the outside to activate the internal circuit and turn the lamp on or off.

However, this method wasn't perfect because I found that only human touch or metal could activate the switch. Using a toothpick or plastic stick didn't work.

Adding a Conductor to the Drilled Hole

Recalling how it works, I realized it needed a conductor to activate. Since I already had the soldering iron and tin wire out, the tin wire was the most convenient conductor, especially since it's soft enough to coil into the hole.

Adding a Decoration to Avoid Ugliness

I found a child's sticker or something similar to cover the hole and make it look less unsightly.